UTD Brain Performance Institute

Location

Size

Design Architect

One-of-a-Kind Brain Performance Center -- Opened in Fall, 2017.

The Brain Performance Institute is the first facility of its kind, providing not only an acute treatment center but also gives people opportunities to help their brains become healthier, more efficient and less stressed. Clients range from professional athletes to corporate executives to military veterans and police offices to teens. The ~67,500 sq. ft. building supports the adjacent UT Dallas Center for BrainHealth, the research home to more than 130 scientists, research clinicians, and graduate students.

Highlights

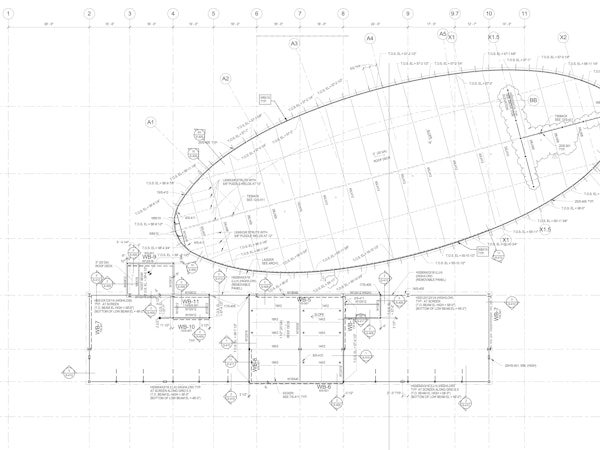

The anatomy of the human brain-inspired the exterior design of the Brain Performance Institute.

Datum created unique processes and solutions to articulate the unusual and complex architectural vision.

Datum’s team developed engineering solutions to make the expensive "Live Lobby" concept affordable.

Process + Persistence = Impressive Solutions

Our structural design process required the study of numerous ways to construct the perimeter columns of the lobby as single steel plates, as opposed to built-up sections. We determined that steel plates would have to resist the wind and gravity loading on the wall with columns as slender as these 2” x 30” steel plate columns, spaced at 5’-0” o.c. To add to the challenge, we wanted to eliminate the added tonnage and the fabrication cost of creating built-up columns. Our research led to the following solution--Horizontal steel 4” x 4” x ½” tube struts were added to the structure at 12’-0” o.c. and welded to the vertical steel plate columns to reduce the unbraced length and twist of the columns. Mission accomplished!

The next pressing challenge was to determine the most economical way to fabricate and erect the steel plate column wall around the Live Lobby. Datum engineers concluded that the most cost-effective solution was to prefabricate three columns connected together in the plant and ship in 10’-0” wide sections. The sections were composed of the three steel plate columns and all of the horizontal struts and beams welded to the columns in the plant. This would leave only lifting, bracing, and attaching the three column panels in the field. Due to the geometry and curvature of the wall, some panels were constructed of two columns. To capture savings for the owner, Datum added details on the structural drawings showing the columns to be prefabricated into panels in the plant and placed using a tilt-wall method of construction. This resulted in significant savings.

Related Documents

Structural Solutions for UTD Article

Download the PDFKey Team Members

Awards

Pursuing LEED Silver Certification

supported by a ring of 78 steel fins, each 62 feet tall, that encircle its perimeter. Designed in collaboration with the revered Dallas engineer Tom Taylor, the 20,000-pound elements march around the exterior, separated by tall windows, creating an accordion effect on the facade. Great job!

Mark Lamster Architectural Record Magazine, July 2018